Steel Scrap Shredder Machine Scrap Metal Crusher for Sale

Basic Info.

| Model NO. | SSX1500 |

| Automation | Automatic |

| Knife Roll | Solid Knife Roller |

| Certification | CE, ISO9001:2008 |

| Power(Kw) | 37*2-95*2 |

| Computerized | Non-Computerized |

| Raw Material | Pet |

| Type | Powerful Plastic Shredders |

| Transport Package | Wooden Case or Container |

| Specification | 1-7 tph |

| Trademark | Yufchina |

| Origin | Henan, China (Mainland) |

| HS Code | 8479820090 |

| Production Capacity | 10000 Set/Sets Per Month |

Product Description

Description of Double Shaft Shredder

Shredding machine also known as shredder crusher crusher, through cutting, tearing and extrusion to reduce the size of shredded materials.

Shredding machine adopts deceleration motor directly connected worm gear, directly installed on the drive shaft of the shredder, through the size of the gear change to the drive shaft, so that the main drive shaft on the spiral tooth cutter head formed relative motion. The helical tooth cutter head on the main drive shaft is staggered, so that the material into, at the same time by squeezing, tearing, cutting action, so that the material is broken.

Application of Double Shaft Shredder

Parameter of Double Shaft Shredder

| Model | Capacity(TPH) | Power(KW) | Knives Qty.(PCS) |

| SSX800 | 1-3 | 37*2 | 32-50 |

| SSX1000 | 2-5 | 45*2-55*2 | 32-70 |

| SSX1500 | 3-7 | 75*2-95*2 | 70-90 |

Components of Double Shaft Shredder

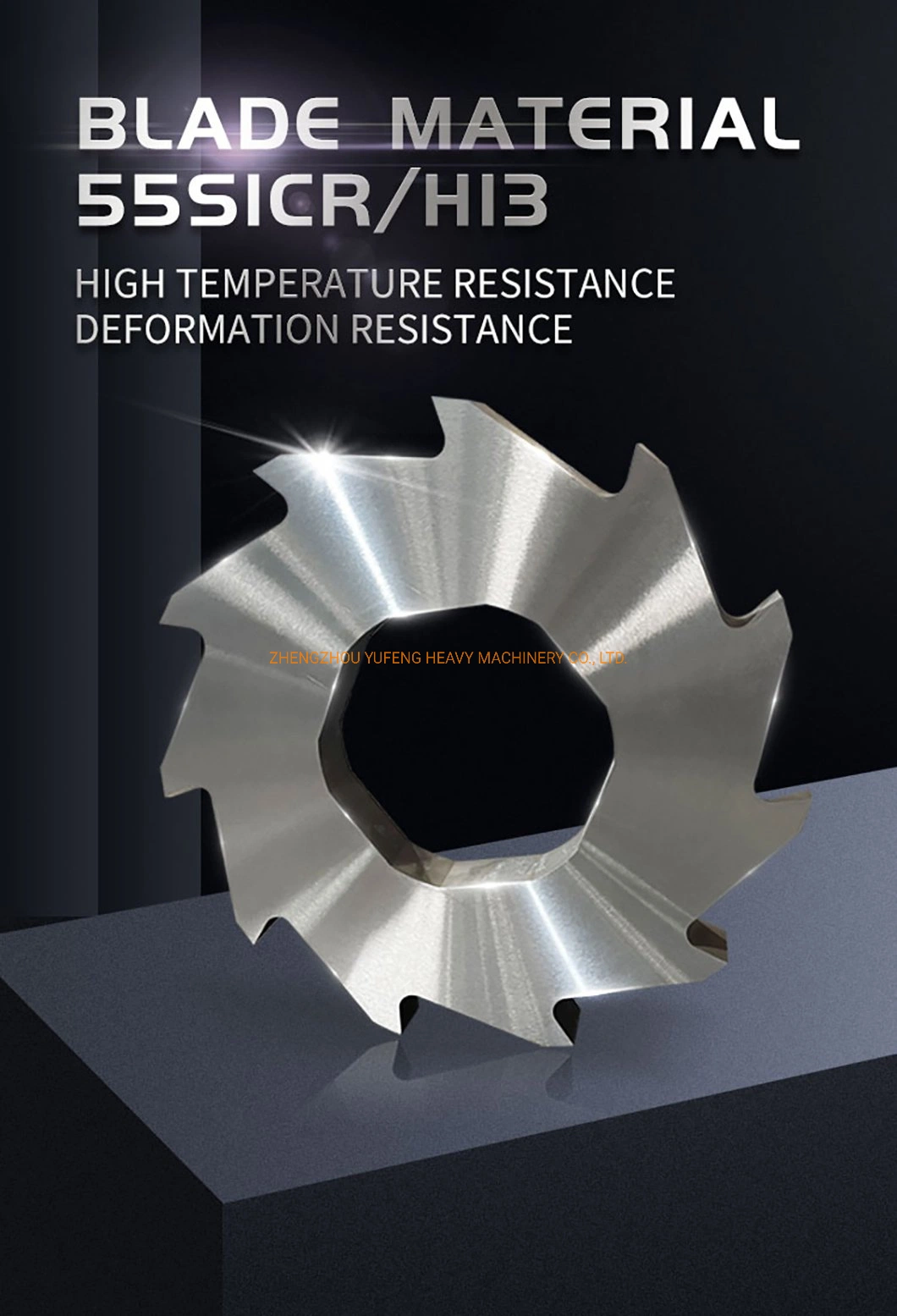

1. The main body of the crusher equipment adopts high quality steel plate welding to eliminate stress processing/overall machining, to ensure the stability of the equipment in the long time heavy load,2. Moving tool/fixed tool moving tool material is made of alloy tool steel forging blank, precision machining, multiple heat treatment and low temperature freezing heat treatment technology. The overall toughness and hardness are consistent and can be repeatedly repaired and used to ensure the cutting performance and service life. The fixed tool is installed by hook type, which optimizes the tool replacement function and makes the tool maintenance and replacement more efficient. 3. The bearing/seal bearing seat adopts the splicing and disassembly type, which can quickly remove the moving tool, fixed tool, bearing and other parts, easy to maintain and replace the tool. The special sealing structure can effectively block the contact between the broken material and grease, and can also protect the bearings and gears when dealing with liquid materials. 4. The tool shaft is processed with high-strength and heavy-duty steel, which more reasonably matches the tool to provide powerful power for cutting.

Performance Characteristics of Double Shaft Shredder

1. This product for a shaft crusher powder of large material, basket material, pipe, plate, wood, tire, scrap metal barrel, large roll film can be broken; 2. Thick plate precision machined composite structure frame, large Angle hexagonal column strong rotation shaft, large caliber solid input hopper, so you can be assured to put large raw materials; 3. In the thickness, shape, arrangement and other aspects of the design and processing rotary knife, strong shear force, sharp blade, can be broken efficiently; 4. Llow speed operation, low noise, less dust; 5. The tool is made of special alloy steel, strong and durable.

SALES AND SERVICE

Pre-sales service1.Tailor-made efficient technical solutions for you.2.Tell us your needs, we will recommend the machine to you, professionally introduce the machine3.Service consultation in 365 days a year.4.24 hours to respond to messages in a timely manner service During the project1.Standardized precision production of production orders in 8 major departments.2. The operation of the machine will be tested before delivery, video will be given to the customer, and the machine will bechecked and accepted3.The entire production process is visualized, which is convenient to check the production progress at any time.4.The idling machine test is combined with the feeder test - strict quality inspection.After-sale service1. Accepting service consultation in 365 days a year.2. Our after-sales engineer can come at any time for maintenance.3. We will return customers on a regular basis, to ensure proper operation of the production line.4. We provide accessories for all equipment.

CUSTOMER CASE

Very welcome your consultation!